| DIY projects No doubt that the top of the line ribbons from Raven and Aurum Cantus are very good, but for most of us also way too expensive. Looking closely at these ribbons they are mostly a big chunk of metal and some really powerfull neodym-magnets plus some smaller parts. Why not make a copy . or even more challenging - make a better ribbon? This was the thought behind a Scandinavian (Swedish) project originating on the newsgroup "hififorum". At this time (end December 2002) a prototype is on the way for a 150 mm high clone. All participians in this project awaits the result with great expectations. The project as it was first intended has been dropped, but we are stil a few Scandinavian guys that want to make our own improved Ribbon speakers! |

Bengt Dahlbergs 13lbs iron parts for the first prototype. |

||

|

Latest news - February 2003! The project is getting somwhere now! Bengt has his prototype up and running. Just with ferrite (samarium-cobalt magnets for now) so the sensitivity is only around 82 dB. First measurements showed a nasty peak around 13.200 Hz.but the new on (se below) is quite promising. A fine baffle has been included (the nice pictures on each side of the ribbon) and another corrugation has been implementet, but the damping of the back chamber still has to be perfected. And then of couse we have to try this out with the neodym magnets!

|

Here Dahlbergs test set-up with samarium-cobalt magnets

|

||

|

Out final target is a frequency range from 500 Hz til at least 20.000 Hz and sensitivity close to 100 dB or above. First we tried to get the magnets from China as they are very expensive here in Scandinavia. Now a Swedish distributor has matched the price from China, but we have to order 100 magnets. The price is approx 2.000 SKR (US$ 250). for two sets of N36 Neodym magnets - 4 pieces 150x40x25 mm (5.9"x1.6"x1"). This means we have to buy magnets for 25 sets, but right now we are only 8! |

Tools of the trade - another gizmo to make the corrugation |

||

| The German Femm programme has been used to

calculate the magnetic properties of the core. This programme can be

downloaded free here:

http://femm.berlios.de

|

... and the ribbon - here 150 cms long (60") |

||

|

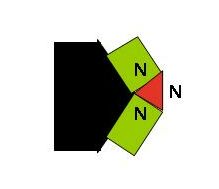

Using Femm the properties of the prototype has been calculated. This calculation has been made by Bengt Dahlberg and shows close to one Tesla in the gap - same strength as the Raven 3.1. |

A DIY corrugating tool |

|

|

A closer look at the poles tells how even small

changes can make a difference.

|

|

|

| Bigger DIY Ribbons

I have made a lot of ribbon speaker myself. A few years ago everyone here in Denmark made big ribbonspeakers inspired by the succes of Apogee. I still have plans for new ones - but this time with neodym magnets!

|

|

80 kgs of big flat ribbon speaker. They ran

with bi-amping through an active tube x-over. The amp for the mid/treble

ribbon drove the 0,5 ohm directly (designed to do it!)

|

|

|

The right speaker in the nude. Height is 180 cm and they were 80 cm wide at the bottom. The woofer section was made like Magnepan but with glued on alufoil. It never worked properly. A lot of power in the bass, but no control. |

|

|

| A friend of mine build a very big 3-way ribbon system. He used 3 times as many magnets as in my "little" system. Despite a very big 200 W Tandberg amp these speakers never made it - actually he never finished the project. But the mid/high were the best ribbons I have ever experienced.. |  |

||

|

|

|||

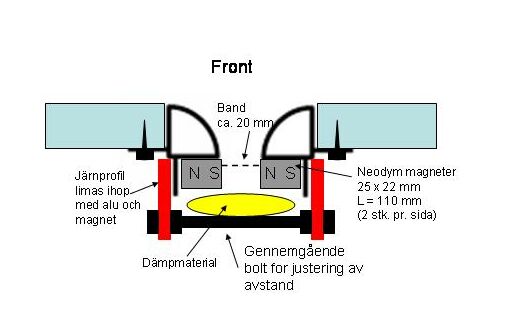

| Porsa

Ribbon My latest project - a new short ribbon using the Porsa alu profiles. This one will be 250 mm high, and I hope to get a reasonable high senisitivity as well as a frequency range that will reach down to about 1 kHz. Each ribbon will use 4 really big and powerfull Neodym

magnets. The grey on the drawing is in fact 2 magnet on each side.. |

|

||

|

First prototype with simple X-former wound on a ferrite core. Load is 1.5 ohm and sensitivity approx 100 dB/1 W. With a simple 1st order Xo at 1.000 Hz the sound is fantastic! | ||